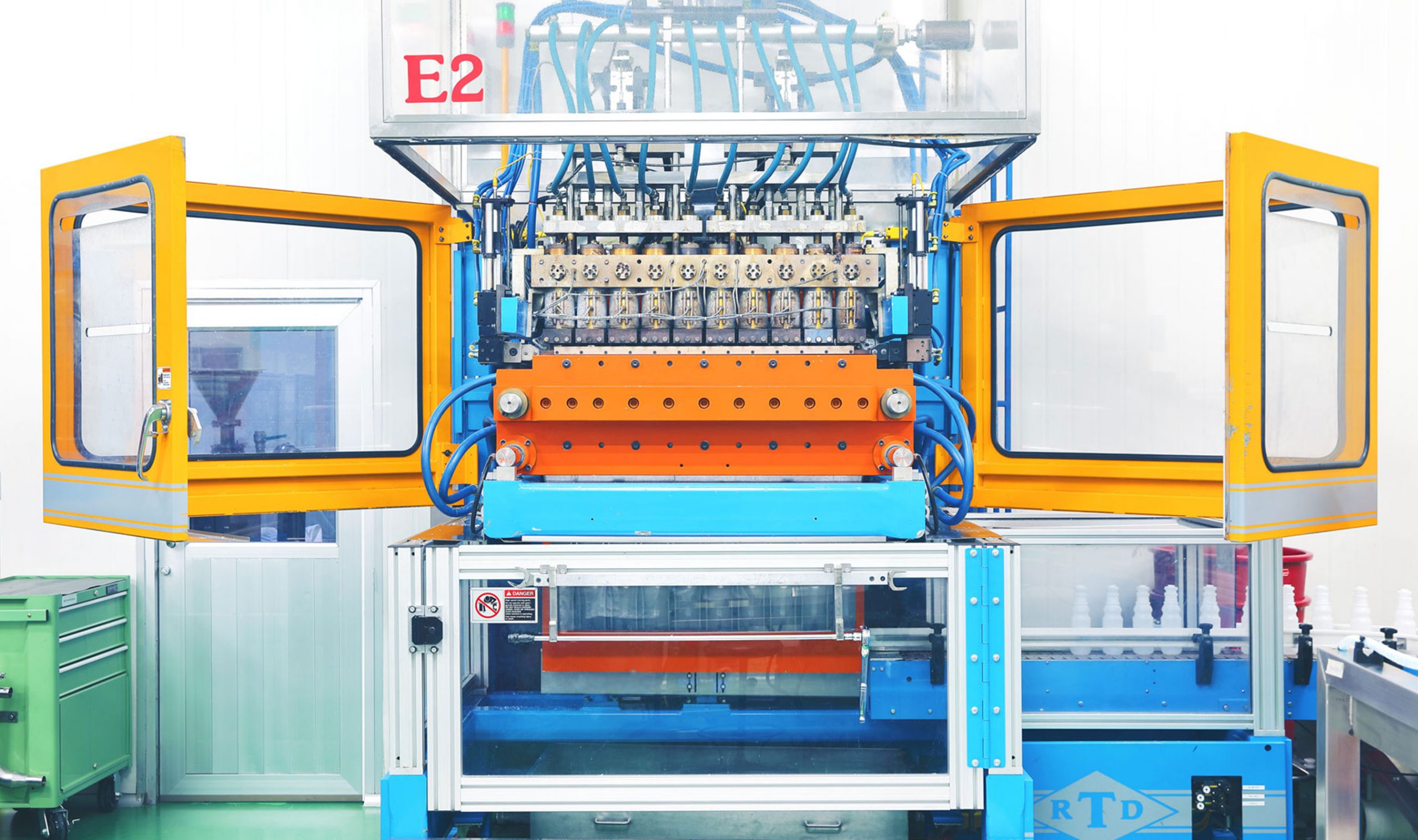

TPAC’s shop floor encompasses the full spectrum of technologies required for rigid plastic processing.

Our secondary processes include

Decoration

(Labelling, Wrap around BOPP Label, Shrink sleeves, Front and back Stickers, Water transfer / cubic print, Spray painted parts, Metalized coating, Form-Fill-Seal)

Printing

(Off Set Printing, UV Screen printing, Pad printing, Hot stamping)

Assembly

(Multi-component Caps, Multi-component Packaging, Multi-component engineering products, Wad and foil insertion)

Best in class infrastructure and machinery platform, no compromise philosophy.

On line camera inspection systems, as well as take-out packing robots also applied across our shop floors.